Plucky Startups Are Driving Innovation in 3D Printing

3D printing tech is still in its infancy, but some startups are already looking to shake things up.

Credit:

Credit:

Recommendations are independently chosen by Reviewed's editors. Purchases made through the links below may earn us and our publishing partners a commission.

3D printing, at least as a consumer technology, is young but already quite entrenched, with only a few brands commanding a large chunk of the market share.

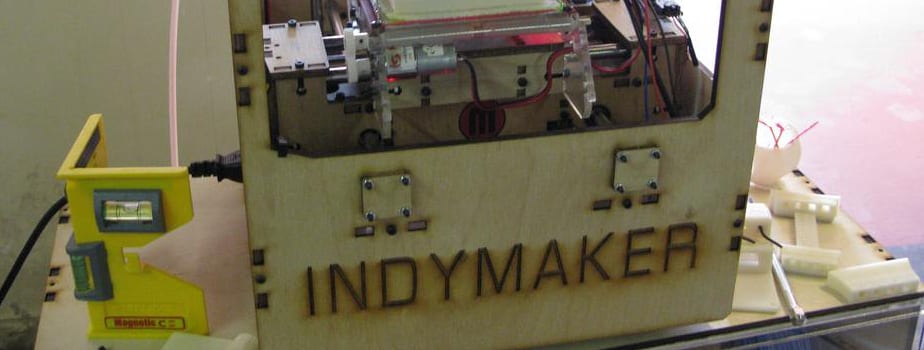

But as 3D printing begins to gather steam, the established brands, such as MakerBot and Afinia, are starting to feel pressure from plucky startups introducing some very interesting innovations.

Currently, most 3D printers on the market are based on a process called Incremental Polymer Deposition, or IPD. As the name suggests, it involves laying down extremely thin layers of melted plastic polymer on top of each other, gradually creating three-dimensional structures. The result is a solid piece of plastic that's usually noticeably ridged where the deposited layers meet.

One of the hot new 3D printing startups is Formlabs, which we profiled last year. The Form 1, their flagship printer, uses an alternative to IPD called stereo lithography (SLA). Rather than melting and then depositing the plastic, the Form 1 uses photo-reactive liquid polymer resin that hardens when hit by certain wavelengths on laser light.

By tracing a stage submerged in the liquid resin with highly focused lasers, the printer incrementally builds the objects as the stage is slowly lifted from the resin bath. Objects printed in this way are less ridged and more precisely crafted than those produced with IPD, making Formlabs one of the leaders in high-quality 3D printing.

Abandoning plastics altogether, Mcor is introducing its innovative Isis printer. Instead of polycarbonate, it uses a more traditional print medium: paper.

The Isis takes regular printer paper, like the kind used in your Canon or HP inkjet, and uses a blade and glue to cut the layers and adhere them to each other. The resulting solid papier mâché object is touted to be as durable and workable as its plastic equivalent, as it "essentially is reconstituted wood."

Mcor ups the ante by also incorporating traditional 2D printer functionality, allowing the user to print millions of colors in the edge of their paper layers before gluing them together. This gives the 3D-printed object not just the desired shape, but also the desired coloring. As a result, objects printed from the Mcor Isis are more realistic and life-like than those printed using other methods.

As in most other markets, innovation in 3D printing is coming not from the big names, but from the hungry start-ups. The companies hoping to make it big here at CES 2014 are showing off their latest and greatest, and we can’t wait to see it.

Photos: Flickr users "creative_tools" (CC-BY-SA-3.0), "wfiupublicradio" (CC-BY-SA-3.0)